In the rapidly evolving global marketplace, international B2B buyers face a significant challenge when sourcing the right carborundum formula for their manufacturing needs. This guide is designed to simplify the complexities associated with procuring carborundum, a crucial material known for its hardness and thermal properties. Whether you are an industrial buyer from Africa, South America, the Middle East, or Europe, understanding the nuances of carborundum sourcing can lead to more informed purchasing decisions and better alignment with your operational requirements.

This comprehensive guide will delve into various aspects of carborundum, including its types, applications, and the critical factors to consider when vetting suppliers. You will discover insights into pricing structures, quality control measures, and logistics that can impact your overall procurement strategy. Additionally, the guide will provide actionable tips on how to navigate supplier relationships, ensuring you choose partners who not only meet your specifications but also contribute to your long-term business goals.

Empowered with this knowledge, B2B buyers can mitigate risks and capitalize on opportunities in their respective markets. By leveraging our expertise, you will be well-equipped to navigate the global landscape of carborundum procurement, ultimately leading to enhanced productivity and profitability for your organization.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicon Carbide (SiC) | High thermal conductivity and hardness | Abrasives, semiconductors, LED technology | Pros: Excellent durability; Cons: Higher cost than alternatives. |

| Carborundum Abrasives | Variety of grit sizes and bonding types | Metalworking, woodworking | Pros: Versatile applications; Cons: May wear out quickly under heavy use. |

| Carborundum Ceramics | High wear resistance and thermal stability | Aerospace, automotive parts | Pros: Lightweight and strong; Cons: Brittle nature can lead to breakage. |

| Reaction Bonded SiC | Enhanced mechanical properties and density | Electronics, chemical processing | Pros: Great for high-stress environments; Cons: Limited availability. |

| Sintered Silicon Carbide | High purity and improved mechanical strength | Oil and gas, mining | Pros: Superior performance; Cons: Expensive and requires specialized handling. |

Silicon Carbide (SiC) is renowned for its exceptional thermal conductivity and hardness, making it a preferred choice in various high-performance applications. It is commonly utilized in abrasives, semiconductors, and LED technology. B2B buyers should consider the initial investment, as SiC can be more expensive than other materials; however, its longevity and efficiency often justify the cost in demanding environments.

Carborundum abrasives come in a wide range of grit sizes and bonding types, which makes them suitable for various metalworking and woodworking applications. Their versatility is a significant advantage for businesses that require different abrasive solutions. However, buyers should be aware that while these abrasives are effective, they may wear out more quickly under heavy use, potentially leading to increased replacement costs.

Carborundum ceramics are characterized by their high wear resistance and thermal stability, making them ideal for aerospace and automotive parts. These materials are lightweight yet strong, providing excellent performance in challenging conditions. Buyers should consider the brittleness of these ceramics, as they can be prone to breakage if not handled properly, which may lead to additional costs in product replacement and handling.

Reaction Bonded Silicon Carbide combines enhanced mechanical properties with increased density, making it suitable for electronics and chemical processing applications. This type of carborundum is particularly advantageous in high-stress environments where durability is critical. However, its limited availability can pose challenges for B2B buyers looking for consistent supply.

Sintered Silicon Carbide is known for its high purity and improved mechanical strength, making it particularly effective in oil and gas and mining applications. While it offers superior performance, the costs associated with sintered silicon carbide can be significant, and it requires specialized handling to avoid damage. Buyers should weigh these factors against their specific operational needs to determine its suitability.

Related Video: Types of Photosynthesis in Plants: C3, C4, and CAM

| Industry/Sector | Specific Application of carborundum formula | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Abrasive materials for grinding and polishing parts | Enhances surface finish and reduces production time | Ensure consistent quality and compliance with industry standards |

| Electronics | Semiconductor manufacturing | Increases efficiency and reliability of electronic devices | Verify purity levels and sourcing from certified suppliers |

| Metal Fabrication | Cutting tools and abrasive wheels | Improves cutting speed and tool longevity | Focus on durability and application-specific formulations |

| Construction | Concrete and masonry products | Enhances durability and resistance to wear | Look for local suppliers to minimize logistics costs |

| Aerospace | Coatings for turbine blades | Provides thermal protection and extends component life | Seek suppliers with aerospace certification and proven track record |

In automotive manufacturing, the carborundum formula is primarily utilized as an abrasive material for grinding and polishing engine components and other critical parts. This application is crucial for achieving a high-quality surface finish, which directly affects the performance and longevity of automotive products. For international buyers, particularly in regions like Africa and South America, sourcing high-quality carborundum abrasives that meet local manufacturing standards is essential. Buyers should ensure that the suppliers can provide consistent quality and adhere to automotive industry regulations to avoid production delays and ensure product reliability.

In the electronics sector, carborundum is essential for semiconductor manufacturing, where it is used in the production of silicon wafers. The purity of carborundum is paramount, as impurities can lead to defects in semiconductor devices, affecting their efficiency and reliability. For B2B buyers from Europe and the Middle East, it is critical to verify the purity levels of carborundum sourced from suppliers. Additionally, suppliers should have certifications that ensure compliance with international electronics manufacturing standards, which can significantly impact the performance of electronic products.

Carborundum is widely used in metal fabrication for producing cutting tools and abrasive wheels. These products enhance cutting speed and tool longevity, enabling manufacturers to improve productivity and reduce costs. B2B buyers, especially in developing regions, should focus on sourcing durable carborundum products tailored for specific applications, ensuring they meet the rigorous demands of metalworking. Understanding the specific requirements of different metal types and the operational environment can lead to more effective tool selection, ultimately boosting efficiency in production processes.

In the construction industry, carborundum is incorporated into concrete and masonry products to enhance durability and resistance to wear. This application is especially valuable in regions with harsh weather conditions, where structural integrity is paramount. For international buyers, particularly from Africa and South America, sourcing locally produced carborundum-infused materials can help reduce logistics costs and improve supply chain efficiency. Buyers should consider the specific environmental conditions of their projects and ensure that the materials sourced are suitable for local climates.

In the aerospace industry, carborundum is used as a coating for turbine blades, providing essential thermal protection and significantly extending the lifespan of critical components. This application is vital for maintaining the performance and safety of aircraft. B2B buyers in this sector, particularly in Europe, must seek suppliers with aerospace certifications and a proven track record of delivering high-performance materials. Understanding the stringent quality requirements and operational conditions of aerospace components is crucial for sourcing the right carborundum products to ensure compliance and reliability in aerospace applications.

Related Video: Akua Carborundum Gel with Wax Mediums

The Problem:

Many B2B buyers, particularly in industries such as manufacturing and construction, face challenges in sourcing high-quality carborundum formula. This is especially prevalent among businesses in regions like Africa and South America, where access to reliable suppliers may be limited. The lack of quality assurance can lead to significant operational issues, including equipment failures and production delays. Buyers often struggle to find suppliers that can provide consistent quality and meet their specific formulation requirements, which can result in frustration and lost revenue.

The Solution:

To overcome these sourcing challenges, B2B buyers should conduct thorough supplier research and establish relationships with reputable manufacturers. Start by evaluating suppliers based on their certifications, production methods, and customer reviews. Consider requesting samples of the carborundum formula for testing before placing larger orders. Additionally, leverage platforms such as industry-specific trade shows and online B2B marketplaces to discover new suppliers. Engage in direct communication to discuss your specific needs and ensure they can provide a consistent product that meets your quality standards. Establishing long-term partnerships with reliable suppliers can lead to better pricing and priority service, ultimately enhancing operational efficiency.

The Problem:

Another common pain point for international B2B buyers is the inconsistent performance of carborundum formula in their applications. For instance, manufacturers in Europe might face issues when the carborundum used in grinding or cutting tools does not deliver the expected results, leading to increased waste and reduced productivity. This inconsistency can stem from variations in raw materials or processing methods used by suppliers, causing frustration and financial strain on production lines.

The Solution:

To address performance inconsistencies, buyers should implement a rigorous testing and validation process for the carborundum formula before full-scale application. This involves conducting trials in controlled environments to assess the performance characteristics of the product. Work closely with suppliers to understand their production processes and the quality control measures they have in place. Additionally, consider collaborating with suppliers to customize the formula to better suit your specific application requirements. By establishing performance benchmarks and continuously monitoring product effectiveness, you can ensure that the carborundum formula meets your operational standards and reduces the risk of production disruptions.

The Problem:

Many B2B buyers, particularly those new to the industry or operating in regions with less technical expertise, often lack the knowledge required to effectively utilize carborundum formula in their applications. This can lead to improper usage, suboptimal results, and wasted resources. For instance, businesses in the Middle East may find themselves unsure about the correct specifications or mixing ratios, which can significantly impact the performance of the final product.

The Solution:

To combat this knowledge gap, B2B buyers should invest in training and education about the carborundum formula and its applications. This can be achieved through workshops, webinars, and training sessions offered by suppliers or industry associations. Additionally, consider engaging with technical experts who can provide tailored advice on best practices for using the carborundum formula in your specific context. Utilize online resources, such as forums and instructional videos, to supplement your learning. By building a solid understanding of the product and its applications, buyers can maximize the effectiveness of the carborundum formula, leading to improved outcomes and a stronger competitive edge in their respective markets.

When selecting materials for the carborundum formula, international B2B buyers must consider various factors that influence product performance and application suitability. Below is an analysis of four common materials used in the formulation of carborundum, along with their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

Silicon carbide (SiC) is one of the primary materials in the carborundum formula, known for its exceptional hardness and thermal conductivity. It can withstand high temperatures, often rated above 1,600°C, making it suitable for high-performance applications. Additionally, SiC exhibits excellent corrosion resistance, particularly against acids and alkalis, which enhances its longevity in harsh environments.

Pros & Cons:

- Pros: High durability, excellent thermal and chemical resistance, and good wear properties.

- Cons: Higher manufacturing complexity and cost compared to other materials.

Impact on Application:

Silicon carbide is particularly effective in abrasive applications and high-temperature environments, making it ideal for industries such as automotive and aerospace.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM C 833 and DIN 3291. It is also essential to consider local sourcing options to reduce shipping costs and lead times.

Aluminum oxide (Al2O3) is another common material used in carborundum formulations. It is known for its high hardness and thermal stability, typically withstanding temperatures up to 1,200°C. Aluminum oxide also has good electrical insulation properties, making it suitable for electronic applications.

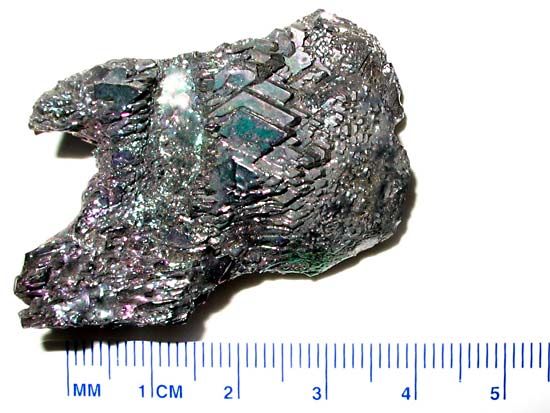

A stock image related to carborundum formula.

Pros & Cons:

- Pros: Cost-effective, good wear resistance, and easy to manufacture.

- Cons: Lower thermal conductivity compared to silicon carbide and less effective in acidic environments.

Impact on Application:

Aluminum oxide is often used in grinding applications and as a filler in various composites, providing strength without significantly increasing weight.

Considerations for International Buyers:

Buyers in regions like Europe should verify compliance with EU regulations regarding material safety and environmental impact, such as REACH.

Zirconium oxide (ZrO2) is utilized in carborundum formulas primarily for its exceptional toughness and resistance to thermal shock. It can endure temperatures up to 2,500°C, making it suitable for extreme conditions. Additionally, zirconium oxide is highly resistant to corrosion and wear, enhancing the durability of the final product.

Pros & Cons:

- Pros: Outstanding thermal stability, excellent mechanical properties, and high resistance to wear.

- Cons: Higher cost and complexity in manufacturing compared to other oxides.

Impact on Application:

This material is particularly beneficial in applications requiring high strength and thermal stability, such as in aerospace and high-performance ceramics.

Considerations for International Buyers:

Buyers should consider the availability of zirconium oxide in their region and its compliance with local standards, such as ASTM D 6400 for compostability if used in environmentally sensitive applications.

Boron carbide (B4C) is renowned for its hardness and lightweight properties, making it an excellent choice for applications requiring high wear resistance and low weight. It can withstand temperatures up to 2,000°C and is chemically inert, which is beneficial in various aggressive environments.

Pros & Cons:

- Pros: Extremely hard, lightweight, and excellent wear resistance.

- Cons: More expensive and less widely available than other materials.

Impact on Application:

Boron carbide is often used in ballistic armor and abrasive applications, providing superior performance in demanding conditions.

Considerations for International Buyers:

Buyers must ensure that boron carbide complies with military and industrial standards, particularly in regions with stringent defense regulations.

| Material | Typical Use Case for Carborundum Formula | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Abrasives, high-temperature applications | Exceptional hardness and thermal stability | Higher manufacturing complexity and cost | High |

| Aluminum Oxide | Grinding applications, electronic fillers | Cost-effective and easy to manufacture | Lower thermal conductivity | Medium |

| Zirconium Oxide | Aerospace components, high-performance ceramics | Outstanding thermal stability | Higher cost and manufacturing complexity | High |

| Boron Carbide | Ballistic armor, abrasive applications | Extremely hard and lightweight | More expensive and less widely available | High |

A stock image related to carborundum formula.

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of materials used in the carborundum formula, enabling informed decision-making that aligns with their operational needs and compliance requirements.

The manufacturing of carborundum, or silicon carbide, involves several critical stages, each essential to ensuring the final product meets the stringent requirements of various applications. For international B2B buyers, understanding these processes can facilitate better supplier selection and quality assurance.

The first stage of manufacturing carborundum involves sourcing raw materials, primarily silica and carbon. These materials are finely ground and mixed in a specific ratio, typically around 70% silica and 30% carbon. This mixture is then subjected to a high-temperature process in an electric arc furnace, which can reach temperatures exceeding 2,500°C.

The quality of the raw materials is paramount; impurities can significantly affect the properties of the final product. Buyers should verify suppliers' material sourcing and processing methods to ensure they meet industry standards.

Once the raw materials are prepared, the next stage is forming. This can involve various methods, including pressing, casting, or extrusion, depending on the desired shape and size of the carborundum product. The pressing technique is commonly used for producing abrasive grains and ceramic parts, where the mixture is pressed into molds under high pressure.

After forming, the product may undergo a process called sintering, where it is heated to a temperature below its melting point to enhance density and strength. This step is crucial as it directly influences the mechanical properties of the final product.

Finishing is the final stage in the manufacturing process and involves several operations to achieve the desired surface quality and dimensional accuracy. Techniques such as grinding, polishing, and coating may be employed based on the application of the carborundum product.

For instance, in the production of abrasive tools, a high level of surface finish is required to ensure optimal performance. Buyers should inquire about the finishing techniques used by potential suppliers to ensure they align with the intended application.

International quality assurance standards play a crucial role in ensuring the reliability and safety of carborundum products. ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 signifies that a manufacturer has implemented consistent quality processes and is committed to continuous improvement.

In addition to general standards like ISO 9001, there are industry-specific standards such as CE marking for products sold in Europe and API standards for petroleum and natural gas industries. These certifications demonstrate compliance with regulatory requirements and are often essential for market access.

B2B buyers should look for suppliers that possess relevant certifications, as this not only indicates adherence to quality standards but also enhances the credibility of the products.

Quality control (QC) is integral to the manufacturing process of carborundum, with several checkpoints established to ensure product integrity. The key QC checkpoints include:

Incoming Quality Control (IQC): This involves the inspection of raw materials upon arrival at the manufacturing facility. Suppliers should provide certificates of analysis (CoA) to confirm the quality and composition of materials.

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are performed to monitor critical parameters. This may include temperature control during sintering and dimensional checks post-forming.

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted to ensure they meet specified standards. This may involve testing for hardness, wear resistance, and other mechanical properties.

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier's quality control measures is crucial. Here are some actionable steps:

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality management systems. Audits can be conducted in-house or by third-party services specializing in supplier evaluations.

Request Quality Reports: Buyers should ask suppliers for detailed quality control reports, including results from IQC, IPQC, and FQC. This transparency helps buyers assess the reliability of the supplier.

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier's quality assurance practices. These agencies can perform audits and tests to ensure compliance with international standards.

When dealing with international suppliers, B2B buyers must be aware of the nuances in quality control that may arise due to geographical differences. Cultural attitudes towards quality, regulatory compliance, and manufacturing capabilities can vary significantly across regions.

For example, suppliers from Europe may have more stringent QC practices compared to those from emerging markets. It’s essential for buyers to communicate their quality expectations clearly and ensure that suppliers can meet these standards consistently.

In conclusion, understanding the manufacturing processes and quality assurance practices for carborundum formula is vital for B2B buyers. By focusing on material preparation, forming, finishing techniques, and rigorous quality control, buyers can make informed decisions that ensure the reliability and effectiveness of their sourced products.

In the competitive landscape of B2B procurement, sourcing a reliable supplier for carborundum formula requires careful consideration and strategic planning. This checklist provides actionable steps for international buyers, particularly from Africa, South America, the Middle East, and Europe, to ensure a successful sourcing process.

What are the specific requirements for your carborundum formula?

Before reaching out to suppliers, it’s essential to clearly outline your technical specifications. This includes the desired purity levels, particle size, and any specific formulation requirements. Having a detailed specification helps suppliers understand your needs and enables you to compare offers effectively.

How can you identify reputable suppliers for carborundum formula?

Conduct thorough research to identify potential suppliers. Utilize industry directories, trade shows, and online platforms to compile a list of companies that specialize in carborundum products. Pay attention to supplier reviews and ratings, as they can provide insights into reliability and product quality.

What certifications should you verify before partnering with a supplier?

It is crucial to confirm that potential suppliers hold relevant industry certifications, such as ISO 9001 for quality management or any specific certifications required in your region. These certifications indicate adherence to international quality standards and regulatory compliance, which can significantly impact the quality of the carborundum formula you receive.

Why is it important to test product samples?

Before making a bulk purchase, always request samples from shortlisted suppliers. Conduct thorough testing to ensure the samples meet your technical specifications and performance requirements. This step helps you avoid costly mistakes and ensures that the product aligns with your operational needs.

How should you approach pricing negotiations with suppliers?

Once you have received samples and verified their quality, compare the pricing from different suppliers. Look for transparency in pricing and be cautious of unusually low quotes, which may indicate compromised quality. Additionally, discuss payment terms to find a mutually beneficial agreement that aligns with your budget and financial practices.

What can references reveal about a supplier's reliability?

Request references from potential suppliers and reach out to their previous clients, particularly those in similar industries. Inquire about their experiences regarding product quality, delivery timelines, and customer service. This feedback is invaluable in assessing the supplier’s reliability and can help you avoid potential pitfalls.

How important is communication in supplier relationships?

Effective communication is vital for a successful partnership. Ensure that you establish clear communication channels with your chosen supplier. Discuss expectations regarding lead times, order updates, and any potential issues that may arise during the procurement process. A supplier that prioritizes open communication is more likely to be responsive and reliable.

By following this practical sourcing checklist, international B2B buyers can enhance their procurement strategy for carborundum formula, ensuring they partner with suppliers that meet their specific needs while minimizing risks associated with sourcing.

When sourcing carborundum formulas, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

Materials: The raw materials for carborundum, primarily silicon carbide, significantly influence overall costs. Fluctuations in the price of these materials due to market demand or supply chain disruptions can impact pricing.

Labor: Labor costs encompass both skilled and unskilled workers involved in the manufacturing process. Regions with higher labor costs, such as parts of Europe, may see increased pricing compared to regions in Africa or South America where labor may be less expensive.

Manufacturing Overhead: This includes costs related to utilities, factory maintenance, and administrative expenses. Efficient operations can help reduce these overheads, affecting the final price.

Tooling: The cost of molds and machinery necessary for producing carborundum can vary widely based on complexity and customization. Investments in high-quality tooling can enhance production efficiency but may increase initial costs.

Quality Control (QC): Ensuring the product meets industry standards requires investment in QC processes. These costs can vary depending on the certifications required for international trade.

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping method, and customs duties can significantly influence the total cost.

Margin: The supplier's profit margin will vary based on competition, market demand, and the perceived value of the product. Understanding this can help buyers negotiate better pricing.

Several factors can influence the pricing of carborundum formulas, including:

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often results in lower per-unit costs. Understanding the supplier's MOQ can help buyers plan their orders effectively.

Specifications and Customization: Customized solutions that meet specific buyer requirements may incur additional costs. Buyers should clearly outline their needs to receive accurate quotes.

Materials and Quality Certifications: The choice of materials and the level of quality certification can greatly affect pricing. Premium quality products will generally cost more due to higher material and processing standards.

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their products due to trust and quality assurance.

Incoterms: International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in shipping. Understanding these can help buyers avoid unexpected costs related to shipping and delivery.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

Negotiate Effectively: Leverage your position as a buyer by negotiating terms that align with your budget and needs. Building a good relationship with suppliers can also lead to better pricing and terms.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with using the carborundum formula, including maintenance, efficiency, and disposal.

Understand Pricing Nuances: Be aware that prices may vary significantly based on the supplier's location, currency fluctuations, and regional economic conditions. This understanding can aid in making informed purchasing decisions.

Research Market Trends: Staying informed about market trends can help anticipate price changes and prepare for negotiations. Monitoring material prices and supplier performance can lead to better strategic sourcing decisions.

It's important to note that prices for carborundum formulas can fluctuate due to various external factors, including market demand, supply chain challenges, and regional economic conditions. Buyers should conduct thorough research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

When evaluating the effectiveness of a product or method in industrial applications, it's crucial to consider viable alternatives. In this section, we will compare the carborundum formula with two alternative solutions that serve similar purposes. This analysis will help B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Carborundum Formula | Alternative 1: Silicon Carbide | Alternative 2: Alumina |

|---|---|---|---|

| Performance | High thermal stability and hardness | Comparable thermal resistance, slightly lower hardness | Good hardness, lower thermal conductivity |

| Cost | Moderate production cost | Generally lower cost | Lower cost than both |

| Ease of Implementation | Requires specialized processes | Easier to manufacture | Widely available |

| Maintenance | Minimal, but specific handling needed | Low maintenance required | Low maintenance required |

| Best Use Case | High-performance grinding and cutting | General-purpose applications | Abrasives and ceramics |

Silicon carbide (SiC) is known for its impressive thermal resistance and hardness, making it a popular choice in various industrial applications. Its performance is similar to that of the carborundum formula but generally comes at a lower cost. The ease of implementation makes it an attractive option, especially for manufacturers looking to streamline their processes. However, while SiC performs well in many scenarios, it may not reach the highest levels of performance required for specialized applications, such as those in aerospace or advanced electronics.

Alumina (Al2O3) is another alternative that is often used in abrasives and ceramics. It is widely available and has a lower production cost compared to both carborundum and silicon carbide. Alumina offers good hardness but falls short in thermal conductivity and overall performance in extreme conditions. This makes it suitable for less demanding applications. Its low maintenance requirements further enhance its appeal, particularly for B2B buyers seeking cost-effective solutions. However, for applications requiring high thermal stability, alumina may not be the best choice.

When selecting between the carborundum formula and its alternatives, B2B buyers should consider specific application requirements, budget constraints, and long-term operational goals. Assessing performance needs against cost and ease of implementation is essential. Buyers in regions like Africa, South America, the Middle East, and Europe should also factor in local availability and supply chain logistics. Ultimately, the decision should align with the overall strategy of the business and its operational efficiency goals. By thoroughly evaluating these aspects, buyers can ensure they choose the most suitable solution for their specific industrial applications.

Carborundum, or silicon carbide (SiC), is a compound that holds significant value in various industrial applications, particularly in abrasives, ceramics, and semiconductor technology. Understanding its technical properties is crucial for international B2B buyers to make informed purchasing decisions.

Material grade refers to the specific classification of silicon carbide based on its purity and physical properties. Higher grades of carborundum, such as green and black silicon carbide, differ in terms of hardness, thermal conductivity, and chemical resistance. For buyers, selecting the appropriate grade ensures compatibility with their manufacturing processes and product requirements.

Grain size is a critical specification that affects the performance of carborundum in abrasive applications. It is typically measured in microns or grit sizes. Finer grains provide a smoother finish, while coarser grains are more aggressive and suitable for heavy material removal. Understanding the desired grain size is essential for buyers to achieve the desired surface quality and efficiency in their operations.

Tolerance levels denote the acceptable variations in dimensions and physical properties of the carborundum products. This specification is vital for ensuring that the materials fit seamlessly into the end-user's production systems, particularly in precision manufacturing environments. Buyers should verify tolerance requirements to prevent costly production delays or product failures.

Thermal conductivity refers to the ability of carborundum to conduct heat. This property is particularly important in applications where heat dissipation is critical, such as in semiconductor manufacturing or high-temperature processes. Buyers need to assess thermal conductivity ratings to ensure that the carborundum materials can withstand operational conditions without degrading.

The hardness of carborundum, typically measured on the Mohs scale, determines its effectiveness as an abrasive. Silicon carbide is known for its exceptional hardness, making it ideal for cutting, grinding, and polishing applications. Buyers must consider hardness ratings when selecting materials for specific industrial applications to achieve optimal performance.

Understanding industry-specific terminology is vital for effective communication and negotiation in the B2B marketplace. Below are essential trade terms related to carborundum procurement.

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of carborundum, buyers may engage with OEMs that incorporate silicon carbide into their products. Understanding OEM relationships helps buyers ensure they are sourcing high-quality materials that meet their specifications.

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it can significantly impact inventory management and cash flow. Understanding the MOQ helps B2B buyers assess the feasibility of procurement and negotiate favorable terms with suppliers.

An RFQ is a formal document that buyers send to suppliers to solicit price quotes for specific products or services. In the case of carborundum, an RFQ should include detailed specifications, such as material grade, grain size, and quantity. This process is vital for ensuring competitive pricing and obtaining accurate proposals from potential suppliers.

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process. For carborundum transactions, understanding Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for managing logistics and risk. It helps buyers anticipate costs and responsibilities associated with transportation.

Lead time refers to the duration between placing an order and receiving the goods. Understanding lead times for carborundum procurement is vital for buyers to manage production schedules and inventory levels effectively. Buyers should factor in lead times when planning their operations to avoid disruptions.

By comprehending these technical properties and trade terminologies, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can navigate the complexities of carborundum procurement with greater confidence and efficiency.

The carborundum formula sector is experiencing transformative changes driven by several global factors. The increasing demand for advanced materials in industries such as automotive, aerospace, and electronics is significantly boosting the market. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are looking for suppliers who can provide high-quality carborundum products that meet stringent performance standards.

Emerging technologies, such as artificial intelligence and machine learning, are reshaping sourcing practices. Buyers are leveraging data analytics to optimize their supply chains, allowing them to make informed decisions about sourcing and inventory management. Furthermore, the rise of digital platforms has simplified procurement processes, enabling buyers to connect directly with manufacturers and suppliers globally. This shift is particularly beneficial for companies in developing markets, where access to reliable suppliers has historically been a challenge.

Additionally, sustainability is becoming a crucial factor in sourcing decisions. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmentally friendly practices. This trend is not only driven by regulatory requirements but also by consumer demand for sustainable products. As a result, the carborundum formula sector is witnessing a surge in innovations aimed at reducing the environmental impact of production processes.

Sustainability and ethical sourcing have emerged as pivotal considerations for international B2B buyers in the carborundum formula sector. The environmental impact of manufacturing processes, particularly concerning carbon emissions and waste, has prompted buyers to seek suppliers who adhere to green practices. This shift is evident as companies increasingly evaluate the lifecycle of materials and the ecological footprint of their sourcing decisions.

Ethical supply chains are gaining traction as a means of ensuring that raw materials are sourced responsibly. Buyers are now looking for certifications, such as ISO 14001 for environmental management and other green certifications, that verify a supplier's commitment to sustainable practices. These certifications not only enhance the credibility of suppliers but also provide buyers with the assurance that they are contributing to a more sustainable future.

Moreover, the incorporation of recycled materials into the carborundum formula is becoming a priority. Suppliers who can offer products derived from recycled content or that utilize environmentally friendly production methods are likely to gain a competitive edge in the market. By choosing suppliers committed to sustainability, B2B buyers can enhance their brand reputation and meet the growing demand for eco-friendly products.

The carborundum formula, primarily known for its applications in abrasives and semiconductor materials, has evolved significantly since its inception in the late 19th century. Initially developed as a synthetic abrasive material, carborundum gained prominence in various industrial applications due to its durability and high thermal conductivity. Over the decades, advancements in production techniques and material science have expanded its applications into diverse fields, including electronics and automotive manufacturing.

As the global economy has shifted towards sustainability and ethical practices, the carborundum sector has adapted by focusing on more eco-friendly production methods and ethical sourcing of raw materials. This historical evolution highlights the sector's ability to respond to market demands and regulatory changes, positioning it as a vital player in the broader context of advanced materials. For B2B buyers, understanding this evolution is crucial for identifying reliable suppliers and anticipating future trends in the market.

How do I choose the right carborundum formula supplier?

Choosing the right supplier for carborundum formulas involves thorough research and vetting. Start by assessing suppliers’ industry experience, certifications, and customer reviews. It’s crucial to request samples to evaluate product quality firsthand. Verify the supplier's compliance with international standards and regulations, particularly for the regions you are sourcing from, such as Africa or Europe. Engage in direct communication to gauge their responsiveness and willingness to meet your specific needs, ensuring they can handle your order volume and customization requirements.

What are the minimum order quantities (MOQs) for carborundum formulas?

Minimum order quantities (MOQs) for carborundum formulas can vary significantly based on the supplier and the specific formulation. Typically, MOQs can range from a few hundred kilograms to several tons. It’s essential to discuss your volume needs with potential suppliers to understand their limits and flexibility. Some suppliers may offer lower MOQs for initial orders, especially if you’re testing a new product. Additionally, consider the logistics and storage costs associated with larger orders to optimize your procurement strategy.

What payment terms should I expect when sourcing carborundum formulas?

Payment terms for carborundum formulas can differ based on supplier policies, the relationship you establish, and the size of your order. Common arrangements include full payment in advance, a deposit with the balance upon delivery, or net payment terms (e.g., net 30 or net 60 days). Negotiating favorable terms is vital, especially for international transactions where currency exchange and transaction fees may apply. Always ensure that payment methods are secure, and consider using letters of credit for larger transactions to mitigate risks.

How can I ensure quality assurance for my carborundum formula orders?

To ensure quality assurance, request comprehensive documentation from your supplier, including product specifications, safety data sheets, and quality control protocols. Establish clear quality benchmarks prior to order placement and discuss the supplier’s testing processes. Conduct regular audits or inspections, either through third-party services or by visiting the facility, to verify compliance with your standards. Implementing a quality assurance agreement can also help maintain product consistency and reduce the risk of defects.

What customization options are available for carborundum formulas?

Many suppliers offer customization options for carborundum formulas to meet specific application needs. Customizations may include variations in grain size, purity levels, or additives that enhance performance characteristics. When discussing customization, clearly outline your requirements and inquire about the feasibility and potential impact on lead times and costs. Some suppliers may provide formulation adjustments based on your application, such as abrasive performance or thermal conductivity, making it essential to communicate your technical specifications effectively.

How do logistics impact the sourcing of carborundum formulas?

Logistics play a crucial role in the sourcing of carborundum formulas, particularly for international buyers. Factors such as shipping methods, freight costs, and delivery times can significantly affect your overall procurement strategy. It’s important to understand the supplier’s shipping capabilities and any associated costs, including customs duties and taxes. Collaborating with logistics partners who are experienced in international shipping can help streamline the process and ensure timely delivery while minimizing disruptions.

What are the key regulations to consider when importing carborundum formulas?

When importing carborundum formulas, it’s vital to comply with both local and international regulations. Key regulations may include import tariffs, safety standards, and environmental compliance related to the materials used. Research the specific requirements for your target market, such as those set by the European Union or local African regulations. Engaging a trade compliance expert can help navigate complex regulations and ensure that all necessary documentation, such as import permits and certificates of origin, is in place.

How can I manage risks when sourcing carborundum formulas internationally?

Managing risks in international sourcing of carborundum formulas involves several strategies. Start by diversifying your supplier base to avoid dependence on a single source, which can mitigate supply chain disruptions. Conduct thorough due diligence on suppliers to assess their financial stability and operational capabilities. Additionally, consider using contracts that include clear terms and conditions regarding delivery, quality, and penalties for non-compliance. Staying informed about geopolitical factors and trade agreements in the regions you are sourcing from can also help anticipate potential risks.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of carborundum formula is essential for international B2B buyers looking to optimize their supply chains and improve cost efficiency. By partnering with reliable suppliers, businesses can ensure high-quality materials that meet their production needs, particularly in industries such as automotive, electronics, and abrasives. Understanding local market dynamics in regions like Africa, South America, the Middle East, and Europe can further enhance sourcing strategies, enabling buyers to tap into competitive pricing and unique product offerings.

As global markets continue to evolve, staying informed about industry trends and supplier capabilities will be critical. Buyers should prioritize transparency and sustainability in their sourcing decisions, which can lead to long-term partnerships and a robust supply chain. Engaging with suppliers who demonstrate a commitment to innovation and quality can significantly impact operational success.

Embrace the opportunity to refine your sourcing approach for carborundum formula. Take action by conducting thorough market research, leveraging technology for supplier evaluation, and fostering relationships with local manufacturers. By doing so, you can position your business for growth and resilience in an increasingly competitive landscape.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina